Menu

Leading sustainable injection moulding specialist, committed to continuous improvement and delivering innovative and sustainable plastic injection moulded solutions, strengthens its in-house toolroom’s machining capabilities by investing in a new, advanced 3-axis vertical machining centre from MACH Machine Tools.

The new machine’s arrival has had a direct and immediate impact on the company’s toolroom productivity, improving floor-to-floor times and optimising process efficiencies.

MACH Machine Tools, the CNC and manual machine tool and machine shop equipment supplier to UK, Irish and European component manufacturers and mould tool and die makers, has recently supplied leading sustainable injection moulding specialist, Great Central Plastics (GCP) Ltd., with a new vertical machining centre.

The machine, a DynaPath-controlled MACH MDV 855-S, was installed at GCP’s 10,500sq. ft. facility in Northamptonshire in December 2024, and has significantly increased the machining capacity and capabilities of the company’s toolroom.

The MACH MDV 855-S is the first, production-oriented CNC-controlled machine tool GCP has acquired in its 27-year history and has been positioned in the company’s toolroom adjacent to a number of manual and semi-auto machines.

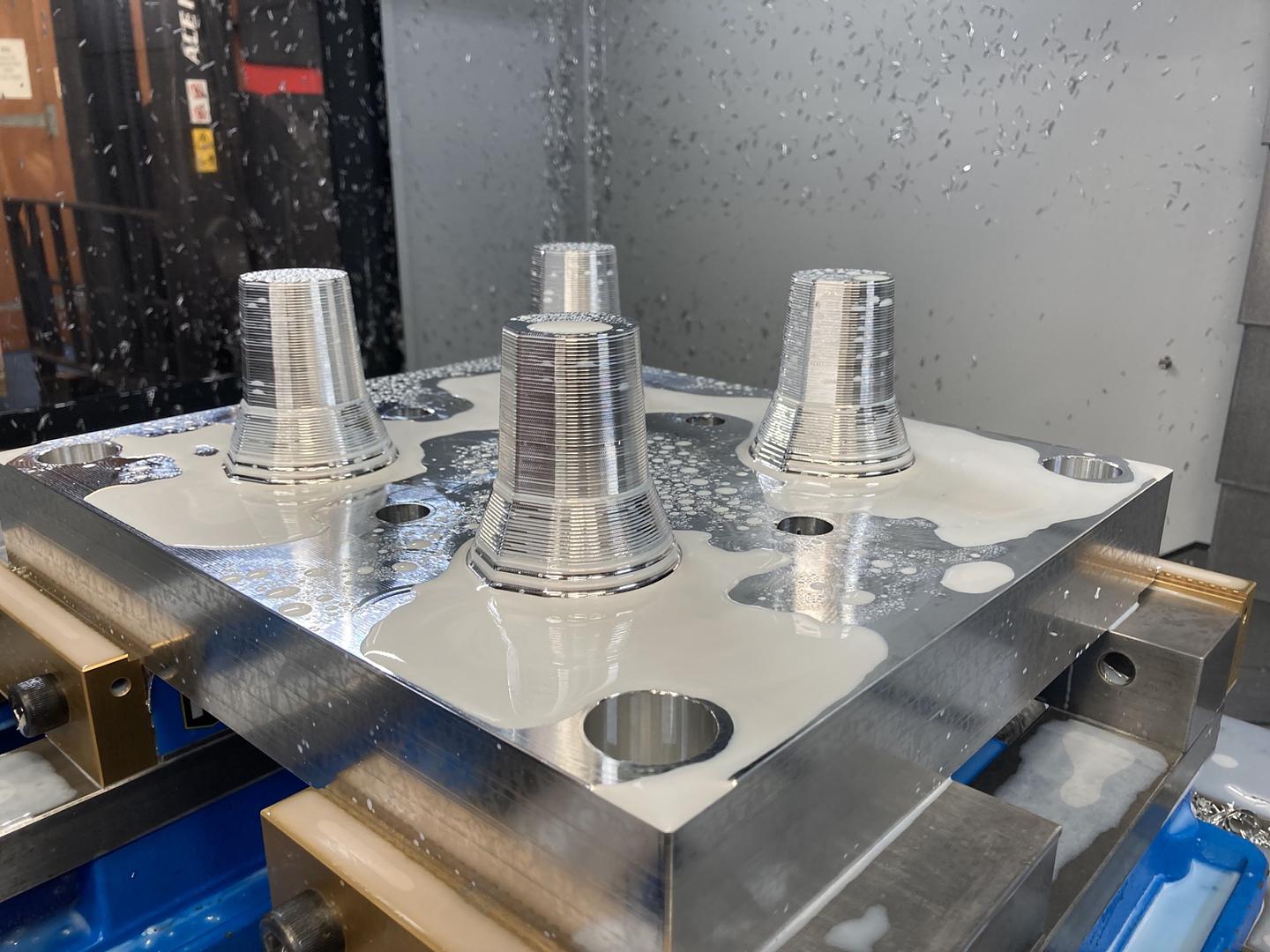

Since being installed, the new machine has been put through its paces machining a range of high-precision mould tool components i.e., bolsters and plates, cavity and core inserts and supporting fixtures etc., for GCP’s custom-designed and built mould tools.

GCP’s mould tools are designed and manufactured in-house in close collaboration with each and every customer.

The company offers expert Design for Manufacturing (DfM) consultancy services to customers in the planning and pre-production stages of every project to ensure that desired plastic parts can be manufactured quickly, easily and cost efficiently.

Pre-production services also include rapid prototyping using 3D printing technology for design validation and testing and, in some instances, as a cost-effective solution for low volume production runs.

For higher volumes, metal mould tools are designed and manufactured (machined) from a range of materials that include aluminium, P20 steel, hardened steel (H13), corrosion-resistant stainless steel etc.

Machining imperatives

GCP’s mould tools are complex, high-precision and performance-critical engineered solutions renowned for their innovation, accuracy and reliability.

They are characterised by their tight, tied-up geometrical tolerances and exacting surface finishes and, having been machined, inspected and signed-off, are moved from the toolroom to the company’s state-of- the-art mould shop which is geared up to manage quick tool and material changeovers.

GCP’s mould shop boasts 14 x injection moulding machines with different capacities and capabilities, and also features a range of finishing equipment – pad printing systems, hot foiling machines etc.

The MACH MDV 855-S investment decision

GCP’s investment in its new MACH MDV 855-S vertical machining centre followed a company-wide review, conducted in Autumn 2024, into all aspects of its design and production operations and processes.

The review highlighted that the company’s toolroom operation needed to be strengthened and that, in order improve existing mould tool manufacturing efficiencies and throughput as well as being able to handle new and more complex mould tool manufacturing in the future, the machining capacity and capabilities of its toolroom needed to be improved.

Says Kiron Phillips, GCP’s Business Development Director:

“We are a successful company committed to growth through continuous improvement.

“As such, we regularly monitor and benchmark operational performance against KPI’s to identify actual and potential pinch-points and bottlenecks, and to address any issues that can or could affect quality, lead time fulfilment and cost efficiencies.

“Our toolroom is pivotal to our success and is the place where new mould tools are manufactured, and older tools are maintained and repaired.

“The toolroom effectively ‘feeds’ our injection moulding machines with high-quality, ‘right-first-time’ mould tools. If the toolroom’s not working to full capacity – neither are our moulding machines.”

As a consequence, following the review, the company made the decision to invest in new CNC machine tool because, according to Kiron Phillips, “we simply could not allow our toolroom to be the weakest link in our process chain, moving forwards.”

The MACH MDV 855-S investment – narrowing down the choice

Prior to investing in the MACH 855-S, the company first did its homework and researched the market.

“We talked to lots of people including other toolmakers about the type of CNC milling machine we were looking to acquire, and the CNC machine tool supplier we would be acquiring it from”, remembers Phil Brown, GCP’s Toolroom Manager.

GCP drew up a technical specification for the new machine that, as well as detailing a budget price, also included:

- the preferred table size to comfortably handle GCP’s standard 20 tonne (246mm x 246mm) and 50 tonne (346mm x 296mm) mould tool plate sizes

- the optimum spindle power and speed range that would enable the company to machine the different materials used for its tools and cope with its high-speed mould tool engraving requirements

- the ideal tool changer size that would help GCP improve part cycle times and reduce time and costs associated with tool changeovers and labour interventions.

Continues Phil Brown:

“As this was going to be our first CNC machine we were also interested in the scope and scale of the different suppliers’ after-sales services and support that could be provided.”

One of the companies GCP contacted was MACH Machine Tools.

Following a visit to MACH’s Bristol facility, where an ex-demo MACH MDV 855-S was introduced to GCP representatives, the company was invited to take part in ‘test cut’ - machining a complex mould tool cavity on the proposed MDV 855-S.

Explains Phil Brown:

“We were impressed with the machine’s ability to deliver the accuracies, surface finishes and processing speeds we were looking for and, once the finance and delivery details were agreed, placed the order for the MDV 855-S.”.

The MDV 855-S: a closer look

MACH Machine Tools’ MACH MDV 855-S is a rigidly-designed and built, high-precision and flexible 3-axis vertical machining centre supplied with the advanced DynaPath CNC control.

The machine is equipped with a generous-sized worktable (1100mm x 500mm) and a powerful 11kW/12,000rpm BT 40 direct-drive chilled spindle, with through-spindle-coolant capability, and features a 24-tool position ATC and impressive 36m/min rapids on its X-, Y- and Z-axes.

The machine’s DynaPath control with a 15.6” LCD touchscreen is inherently versatile and is capable of accepting multiple program formats via its inbuilt USB, ethernet and wireless interfaces.

The DynaPath control is also user-friendly and powerful. It can be used for conversational programming (as well as ISO programming), and has 8GB of memory and a 10,000 block look-ahead capability for fast and smooth contouring and profiling.

The control also enables customers to access MACH Machine Tools’ 24/7 (Wi-Fi) remote service and support facility for real time diagnostics, trouble-shooting and applications help and advice.

Says Phil Brown:

“The remote assistance function is really useful, and I have had occasion to use it when I had an issue with the machine’s tool changer.

“I had made a programming error but, after logging into our company’s account was able, via the ‘What’s App’ link, to talk directly to MACH Machine Tools Technical Support staff to solve the problem quickly - minimising downtime and negating the need for a service visit.”

Although the MDV 855-S has only recently been installed in GCP’s toolroom, it is already making a big difference to the company’s productivity and process efficiencies.

Concludes Kiron Phillips:

“The new machine is proving to be a great investment. We are now able to manufacture our mould tools, and their constituent parts, faster than before.

“This has helped improve our floor-to-floor times and customer lead times too as our injection moulding production operation is no longer ‘waiting’ for mould tools to be finished.”

About Great Central Plastics

Established in 1998, GCP is a high-quality manufacturer of injection moulded products, specialising in creating customised plastic solutions with a strong focus on sustainability and innovation.

The company was originally focused, in the early days, on the promotional industry, manufacturing products for magazine cover mounts and event/exhibition merchandise and ‘give-aways’.

During and following the immediate aftermath of Covid-19, which effectively closed the whole exhibition and events industry down for a significant period of time, GCP re-positioned itself; a case of ‘needs must.’

Concentrating on its key strengths i.e., quick tool and material changeovers, GCP ‘captured the eco-friendly and sustainability wave’ and rode it hard, focusing all its efforts and resources on becoming a sustainable materials’ injection moulding specialist and advocate.

The move has helped GCP differentiate itself in what is a ‘cluttered market’ and, for customers committed to reducing their carbon footprints and meeting their ESG (Environmental, Social and Corporate) targets, the company provides a real and proven way forward.

GCP provides expert advice on the use and application of eco-friendly plastics that include Gum-tec® (made from recycled chewing gum), LIMEX® (a limestone-based material), and Waterhaul® (sourced from abandoned fishing gear and nets).

The focus on sustainability has taken off in recent years and this, along with its expertise using more traditional plastics and a constant investment in cutting-edge production technologies, has helped GCP secure new business contracts with customers in the food and beverage sector (i.e., Aperol, Smirnoff, Cadbury, Petit Filous) and the automotive industry (automotive car badges).

GCP’s sustainability credentials are further underscored with the installation of solar panels on the roof of its facility that generates approximately 30% of the company’s energy requirements, and through its commitment to recycling all waste created during its manufacturing processes.

For further information please contact:

Matt Andrew

matt@machmt.co.uk

Tel: 0117 965 2706