Menu

Milton Keynes College (MK College) has recently invested in four new high-performance MACH VS-1SP manual milling machines from MACH Machine Tools.

This latest investment has significantly increased and strengthened the manual milling capacity and capabilities of the College’s Innovation & Technology Centre’s engineering workshop, located at its Chaffron Way Campus, and has provided its engineering students not only with direct access to modern manual milling technology used extensively by component manufacturers and toolmakers across the UK, but also with the opportunity to acquire relevant and, Industry-sought-after, practical skills to help them secure engineering jobs and careers in the future.

Following a successful tender submission in 2023, MACH Machine Tools, a leading UK-based CNC and manual machine tool and machine shop equipment supplier, has supplied MK College with four new MACH VS-1SP manual milling machines.

The machines, equipped with direct-drive, infinitely variable spindles, large worktables and Digital Read Outs (DROs), are renowned for their accuracy, flexibility, ease-of-use and reliability, and have fast become a staple manual milling machine tool solution for many UK and Irish component manufacturers and, in recent years, for a growing number of UK educational organisations (i.e., FE/HE Colleges, Universities etc.), too.

Since being installed, in Summer 2024, the MACH VS-1SP milling machines have been, and are being, used by a diverse range of MK College students on a number of full- and part-time engineering courses – from entry, intermediate and advanced levels (1, 2 and 3) through to HNC/HND certificates and diplomas - as well as for trainees on local employers’ apprenticeship programmes.

The latest machine tool investment is an integral part of a wider strategic improvement and modernisation programme implemented by MK College to upgrade the machining capacity and capabilities of the engineering workshop, helping to transform it into a world-class engineering training facility, valued by students, apprentices, lecturers and local employers alike, and able to provide MK College students and trainees with relevant, transferable skills and improved employment prospects.

Investment decision

The engineering workshop at MK College’s Innovation & Technology Centre is modern, clean, spacious and well-resourced. In addition to a large bench work area, the workshop also boasts 10 manual lathes and (now) twelve manual milling machines.

Back in 2023 the decision was made, following an internal audit, to upgrade the engineering workshop’s milling capacity and capabilities.

Explains Nick Mussell, Engineering Lecturer at MK College:

“We had ten manual milling machines available in the workshop at that time but a couple of them were ‘long in the tooth’ and, in all truth, had ‘seen better days’.

“As a consequence, we ultimately decided to replace these two older machines with two new models and, to enable us to better accommodate larger class sizes and ensure a ‘one student to one machine’ ratio, also decided to acquire two new additional machines as well.”

From a reliability perspective, MK College made the decision to opt for four new manual milling machines rather than going down the used/pre-owned route.

Continues Nick Mussell:

“We have previously invested in used machines, but this time around decided, from a reliability perspective and the need to avoid potential disruptions to curriculum delivery and teaching schedules caused by machine breakdown, to acquire new machines.”

Tender

As part of the investment process a detailed tender, inviting potential suppliers to submit detailed proposals for the supply (including delivery and installation) of four new, identical manual milling machines was prepared and advertised.

Tender success

As with all MK College tenders, a robust procurement procedure and evaluation process was followed after the tender submissions’ closing date, with every tender received being reviewed against strict published evaluation criteria, to determine the most economically advantageous and best-value submission.

MACH Machine Tools’ tender response was successful for a number of reasons:

• The technical specification of the four manual machine tools proposed, and their price and availability.

• The level of service and support, including delivery, installation, training etc., provided.

Continues Nick Mussell:

“I had previously met representatives from MACH Machine Tools on their stand at the MACH 2022 exhibition in Birmingham and, as a consequence, already had some knowledge of the machines they had in their product range.

“I was particularly interested, and liked the look of, the VS-1SP model and was pleased that this was the machine they were recommending in their tender proposal.”

MACH VS-1SP – a closer look

MACH VS-1SP machines are rigidly-designed and built manual turret-type milling machines.

The machines are equipped with direct-drive, infinitely variable spindles (420 – 5000rpm), large worktables (1245mm x 229mm), with a 340kg maximum table load, and a 2-axis Newall Digital Read Outs (DROs).

Explains Nick Mussell:

“The direct-drive technology on the VS-1SP machines was a particularly strong selling point.

“As well as ensuring improved accuracies and surface finishes, direct drive systems using an inverter motor eliminate backlash typically associated with traditional gear and belt-driven systems and, because there are fewer moving parts compared to belt-driven systems, direct-drive machines are less prone to wear and tear, and costly maintenance.”

Similar performance and operational advantages are also evident from the VS-1SP’s infinitely variable speed spindles which, as opposed to machines with a fixed number of speeds that are adjusted via a discrete gearbox or pulley system, provide a continuous range of speeds that allows the operator to precisely match spindle speeds to machining parameters, the materials being machined and the cutting tools available.

Continues Nick Mussell:

“An increasing number of component manufacturers and precision tool makers use manual machine tools with direct drives and infinitely variable speed spindles which, from a training perspective, makes it incumbent on us to provide our students with access to this type of technology, as well as gaining experience on older, indirect drive and fixed speed manual machine tools.”

MACH VS-1SP machines in use

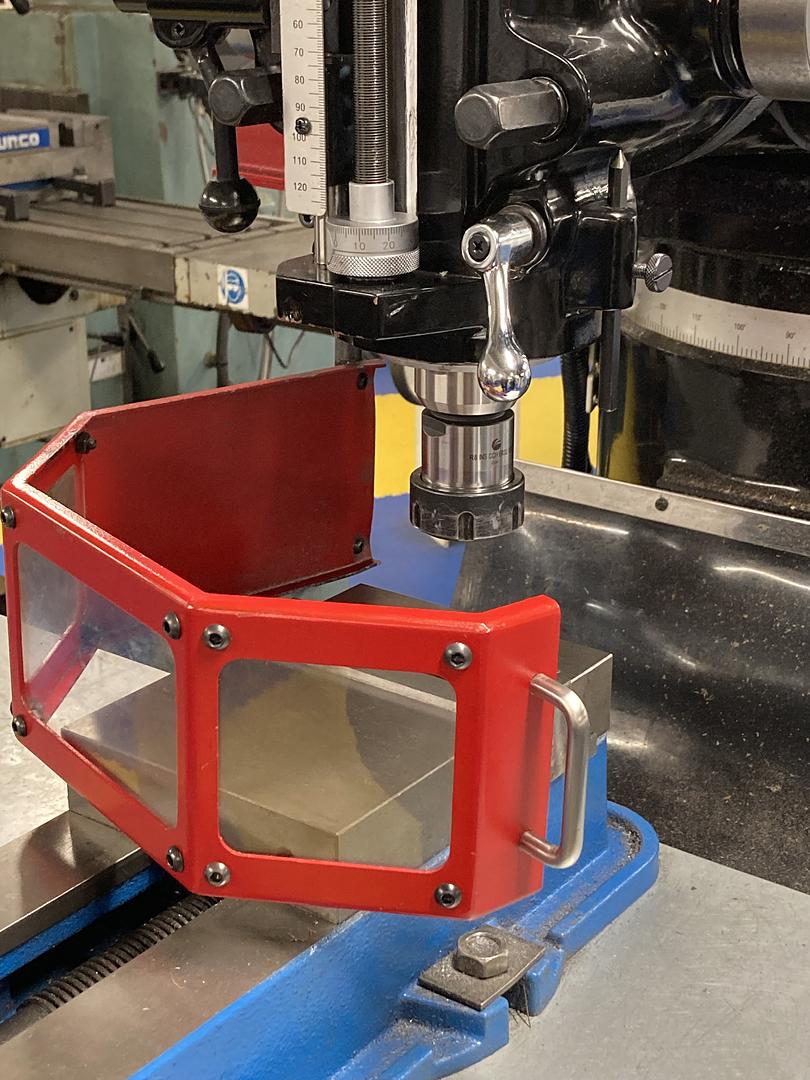

Since being installed in the Summer of 2024, MACH VS-1SP machines, incorporating MK College’s preferred ER32 collet system, have been used by a large number of students to machine small precision parts made from (solid) aluminium and mild steel blocks and billets.

To help the MACH VS-1SP machines integrate and operate more effectively in MK College’s engineering workshop environment, a number of minor modifications to the machines’ structure have been made by College staff – post-installation.

These have included, for example, a) the removal of the machines’ large splash trays as the emphasis at MK College is on ‘dry cutting’ as opposed to machining operations using coolant, b) the manufacture and incorporation of plate covers that have been fixed, in place, over the machines’ existing worktables facilitating easier and faster cleaning and maintenance, and c) making the brackets of the machines’ interlock guards sturdier.

Summary

MK College’s decision to invest in four new MACH VS-1SP manual milling machines has proved to be both prudent and strategically sound.

The arrival of the new machines has allowed MK College students to increase their engineering competencies and acquire relevant and practical engineering skills from operating modern manual milling machines that are used extensively by manufacturers, large and small, all across the UK and have, as a result of this, improved their employment prospects.

For further information please contact:

Matt Andrew

matt@machmt.co.uk

Tel: 0117 965 2706